Filter Products

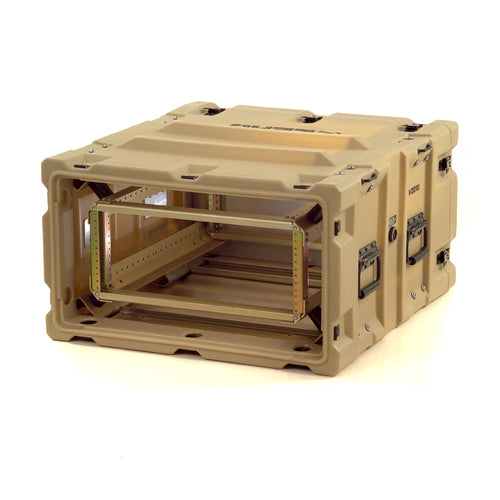

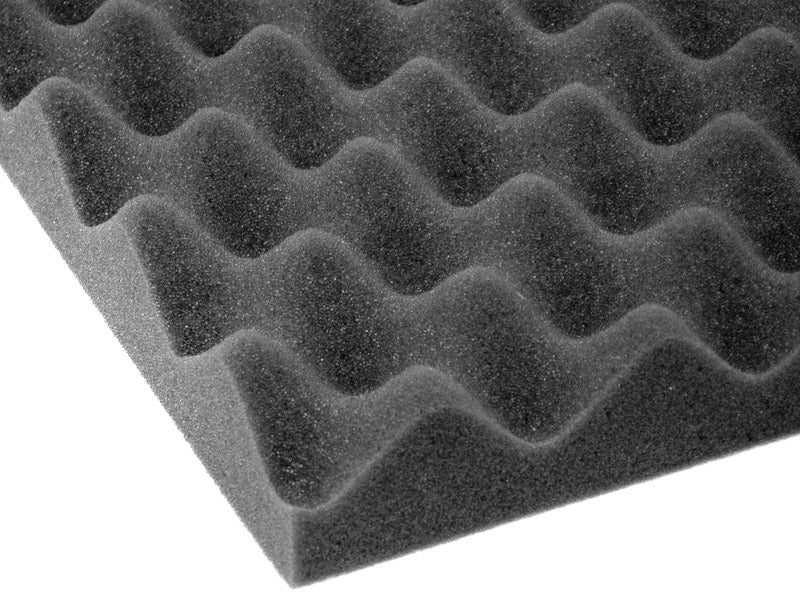

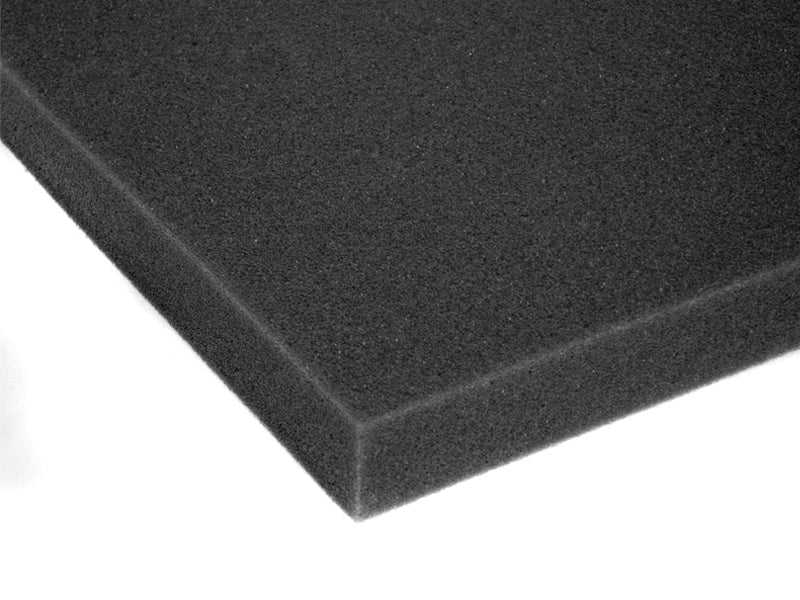

1.5" Convoluted Charcoal Ester Foam Sheet (2lb. Dens.)

- ←

- →

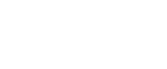

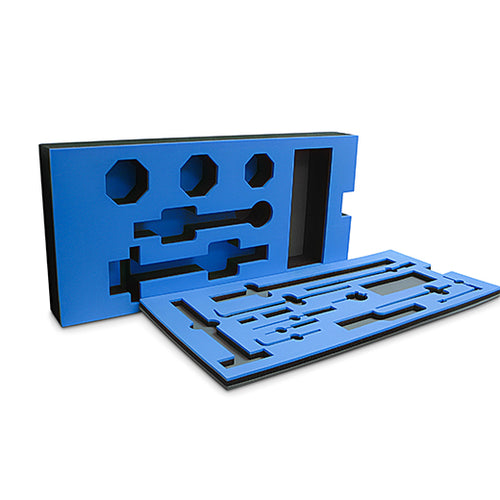

Cases By Source provides single-source solutions for stock and custom case applications. Our waterproof cases, ATA cases, aluminum cases, transit cases, tool cases, and plastic cases offer a multitude of options for commercial, industrial, military, and OEM requirements. Constructed mainly of plastic, aluminum, and wood, our durable and stylized cases—featuring brands like SpectraCase, BudCase, EuroCase,, Praxis, TransCase and more— can be customized to meet your specific requirements. They can be customized with custom foam, molded interiors, or panel mounts to secure, organize, and display your instrumentation and equipment. We have unlimited solutions for the protection and presentation of your valuable products. Contact our sales engineers for a free consultation.