- Cases

-

- All Cases

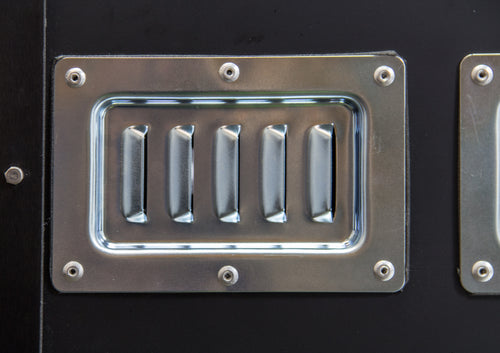

- Aluminum Cases

- ATA cases

- Soft Bags & Cases

- Camera Cases

- Carrying Cases

- Consumer Electronics Cases

- First Responders

- Laptop Cases

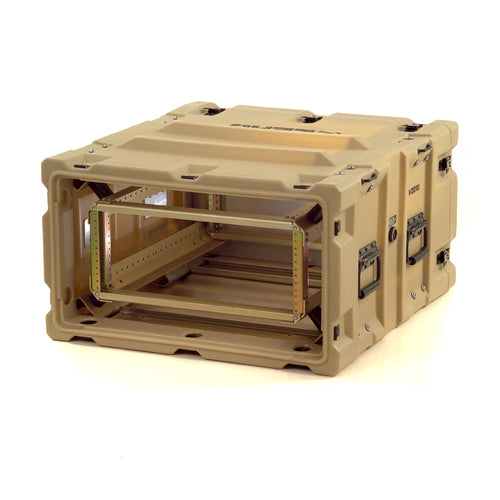

- Military Cases

- Plasma, LCD Screen Cases

- Presentation Cases

- Pro AV Equipment Cases

- Professional Makeup Cases

- Shipping Cases

- Sporting Cases

- Tool Cases

- Trade Show Cases

- Waterproof Cases

- Accessories

- Clearance

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

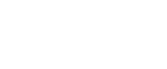

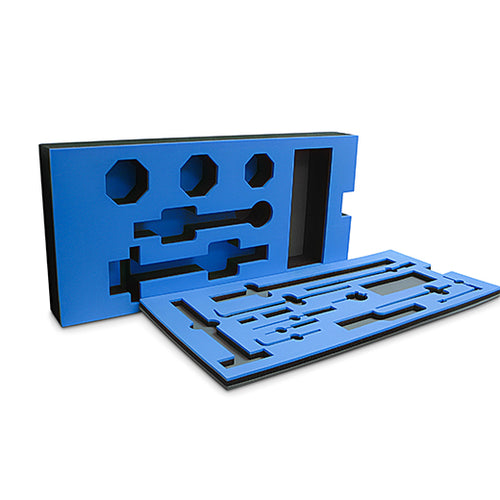

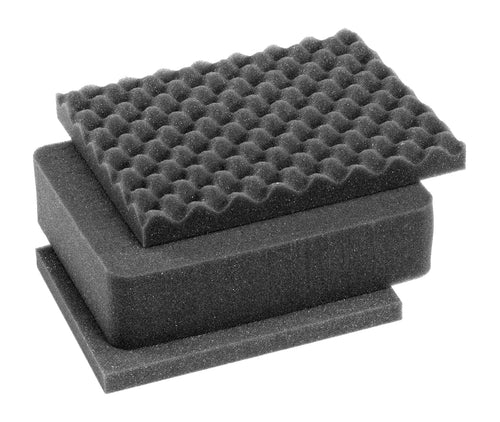

- Foam

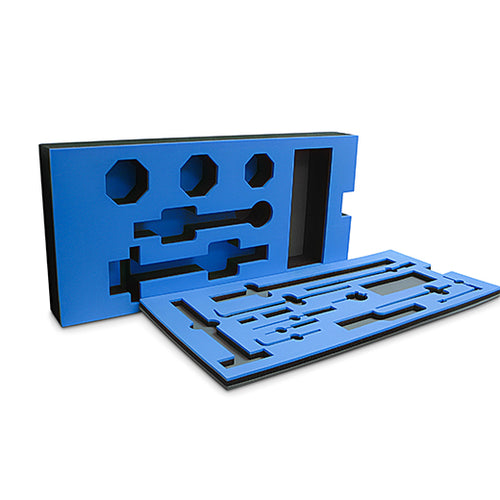

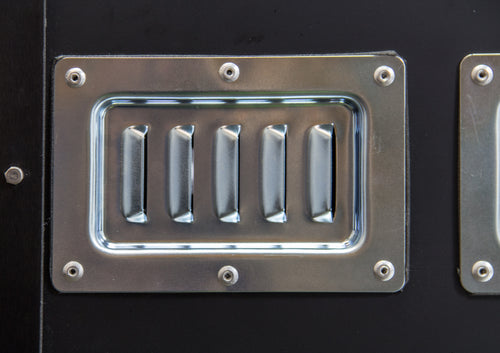

- Rackmounts

- Brands

- CasePro

- Cases

- All Cases

- Aluminum Cases

- ATA cases

- Soft Bags & Cases

- Camera Cases

- Carrying Cases

- Consumer Electronics Cases

- First Responders

- Laptop Cases

- Military Cases

- Plasma, LCD Screen Cases

- Presentation Cases

- Pro AV Equipment Cases

- Professional Makeup Cases

- Shipping Cases

- Sporting Cases

- Tool Cases

- Trade Show Cases

- Waterproof Cases

- Accessories

- Clearance

- Foam

- Rackmounts

- Brands

- CasePro

Need Custom?

Using your needs and specifications as a roadmap, we can design, engineer, and manufacture a custom case that matches your vision. Start the conversation with a free consultation!

Custom SolutionsYour cart is currently empty!